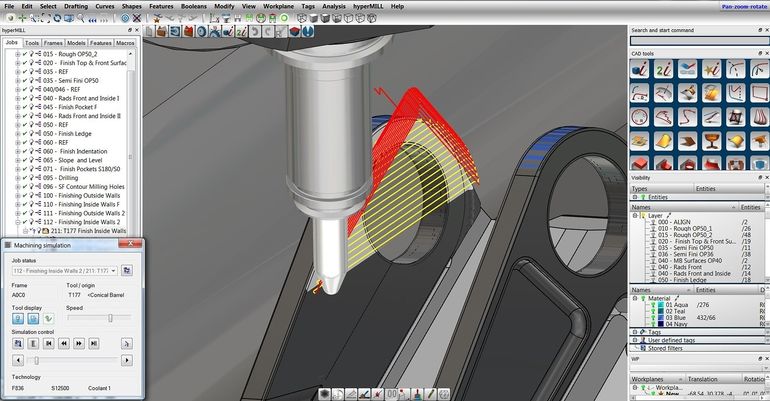

Dynamic feedrate adjustment according to actual cutting conditions ensures milling with the highest possible feedrates at all times. The roughing module in the performance package offers solutions for high-performance cutting (HPC) with spiral and trochoidal tool movements on prismatic and curved component surfaces. The hyperMILL ® MAXX Machining performance package offers three powerful modules that help companies realise significant optimisation potential in roughing, finishing and drilling applications.

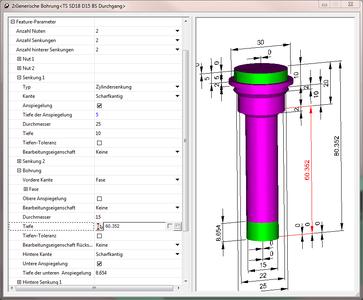

The new Multiple Track Support function allows a separate pitch sequence to be defined for each track. This means that each pitch only has to be programmed once. The user can display the suitable geometry for each operation in order to avoid errors. At its heart is the Tire Clock, where the tire’s design is defined with all segments, tracks, pitch sequences and pitches.Īutomated functions support creating and managing the elements and geometries required for programming. The tire module of the hyperMILL ® CAM suite offers a range of special functions for the NC programming of tire molds.

#What is hypermill software

The package also supports high-performance roughing of both prismatic and curved component faces with five-axis techniques.OPEN MIND Technologies AG, one of the leading CAD/CAM software developers, will be present at Booth 6010 at Tire Technology Expo in Hanover, from 16 to 18 February 2016. This results in optimal milling paths with maximum material removal. Dynamic feed rate adjustment according to actual cutting conditions ensures consistent milling at the highest possible rates. It also includes options that identify large inscribed rectangles or circles within components to optimize machining with simple tool paths and complete the pocket by identifying the regions with remaining material. The roughing module, which is designed for fast, reliable machining, includes cycles for milling spiral and trochoidal tool paths.

According to Open Mind Technologies, five-axis helical drilling uses standard cutters to open large areas prior to roughing and uses a five-axis helical tool path to efficiently remove material and evacuate chips. The performance package of the HyperMill Maxx Machining offers three modules for drilling, roughing and finishing that are designed to help users achieve optimal rates of machining productivity. All toolpaths generate fully automatically with collision checking and avoidance. Users can choose between five-axis machining with a fixed tool angle, automatic indexing or true simultaneous machining. The HyperMill CAM software suite includes a wide range of powerful five-axis strategies designed for machining challenging geometries, free-form surfaces and deep cavities at maximum efficiency levels. HyperMill CAM software includes support for five-axis cavity milling.

#What is hypermill manual

We have never needed to make manual edits to make the programs run properly,” he says. “Open Mind Technologies postprocessing is clean and accurate. A high-precision surface module, which enables him to mill fine surface finishes, and advanced part probing cycles for the Heidenhain Control have also enhanced Katrov’s operation. One such feature is five-axis helical drilling, which enables him to use regular end mills to helically drill large holes at high feed rates. In addition to tangent plane machining, Katrov also relies on other HyperMill features for time and tooling cost savings. “And there are times when this tangent milling with barrel cutters feature provides the only way to effectively machine the required shape of a customer’s part,” he says. Utilizing tangent milling with barrel cutter strategies from the HyperMill Maxx Machining performance package has enabled the shop to manufacture very complex components with standard tooling, which has reduced cycle times by as much as 70%, Katrov says.

0 kommentar(er)

0 kommentar(er)